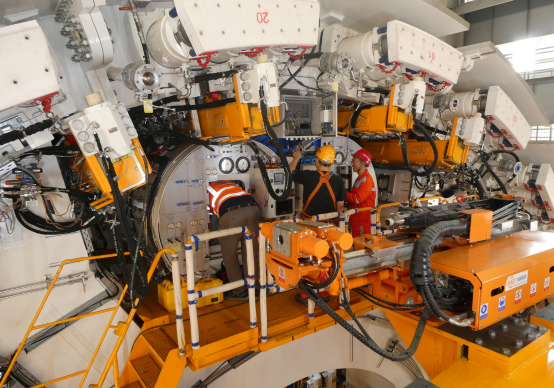

From small-diameter TBM (tunnel boring machine) access locks to large-capacity multi-compartment systems, our solutions are designed to meet your exact operational profile. With a modular approach and robust engineering, we deliver reliable systems ready for the harsh conditions of the tunnelling world.

Product options for tunnelling

- Personnel air locks (2 to 40 persons, single to multi-compartment),

- Ø 1200 – 1800 mm

Material locks in different sizes

- Medical and therapeutic chambers for decompression or treatment

- Mobile life support containers for TBM or shaft sites

- Oxygen breathing systems and gas management panels

- Environmental control units (heating/cooling)

- Monitoring and control systems (manual or computer-aided)

- Complete tunnel saturation Systems for pressures up to 20 bar

Application areas

- TBM operations under compressed air

- Compressed air interventions and hyperbaric maintenance

- Access and rescue operations in pressurised environments

- Segmented shaft and tunnel access via modular chamber setups

- Decompression treatment for tunnel workers

Environmental

- Operational to pressures of 10 bar and beyond

- Support for compressed air workers and medical personnel

- Suitable for extreme underground temperatures

- Explosion-proof (ATEX) configurations available

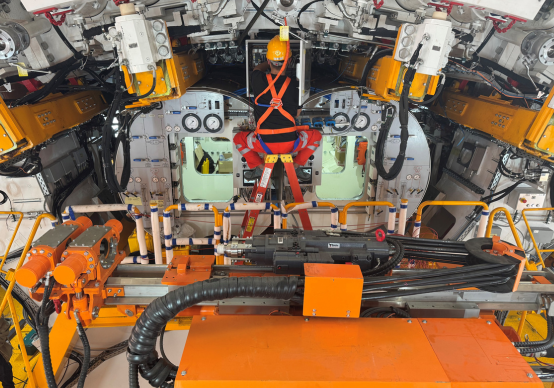

- Custom door types (round/rectangular)

- Modular layout for confined worksite integration

- Options for containerised, stackable, or embedded systems

Standards & Certification

- Manufactured according to international tunnelling and hyperbaric standards

- Compliance with EN 12110, EN 14931 and ASME PVHO guidelines, and many more

- ATEX-certified components for hazardous environments

- ISO 13485 certified design and production process

- Safety valves and pressure control in accordance with PED

High standards

Our systems are designed with durability and user comfort in mind, even in the harshest working conditions. Pressure chambers and locks feature intuitive controls, easy access, and are built with materials resistant to corrosion, impact and extreme temperatures. We ensure the integration of ergonomic layouts, minimal maintenance needs and seamless interfacing with other site systems.

Safety

Safety, reliability and quality is the foundation of everything we build. All systems are engineered with redundancy in critical systems, emergency bypass functionality and real-time environmental monitoring. From fire-resistant interior panels to safe gas delivery systems and automatic pressure controls — every detail contributes to protecting lives in high-risk tunnelling environments.